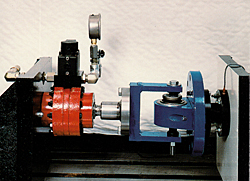

Rubber Dynamic Testing

ESI specializes in the dynamic characterization of rubber products and rubber materials.

Dynamic testing involves exciting a product or material sample with a controlled input and measuring the resulting response. A sinusoidal waveform input as a load or displacement signal is a common type of excitation imposed with a high performance servo-hydraulic actuator. The reaction load measured across the sample, the phase shift and the displacement signal are used to calculate engineering parameters, typical properties include:

- Complex Dynamic Stiffness K*

- Storage Stiffness K’ or Kd

- Loss Stiffness K”

- Damping C

- Phase Φ

- Tan Delta δ

- Compression, Tension or Shear Moduli E*, E’, E”, G*, G’, G”

- Transmissibility Tr

- Energy Absorption

- Natural Frequency

- Hysteresis

- Resilience

- Fatigue Crack Growth Rate

Using servo-hydraulic (MTS) and electrodynamic (Labworks, Ling) test systems ESI can determine material and engineering properties from the static condition to well over 1000 Hz. We have test machines capable of imparting dynamic loads up to 110 Kip (500 kN) and 17 inches (432 mm) of dynamic stroke.

Test input variables may include:

- Frequency

- Preload or prestrain

- Dynamic amplitude (load, displacement or acceleration)

- Temperature