Fatigue Testing

Material fatigue tests include Fatigue Crack Growth (FCG) testing of pure shear specimens, 3 point bending flex and Demattia style rubber coupon testing.

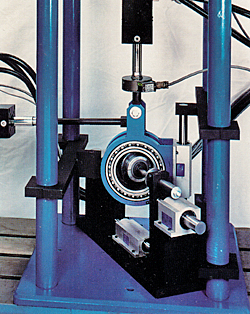

Fatique tests often require custom designed fixtures and tests. We have more experience in tooling design, system integration and computer controlled analysis of automotive rubber-to-metal bonded products than any other independent laboratory. Our engineers have decades of experience in mechanical goods rubber design, testing, and manufacturing as well as access to the latest computer software and hardware technology

Product fatigue testing is offered on polymer based (rubber and plastic) as well as ferrous and nonferrous metal components. Each test can be custom designed to input multi-axis loads, angles and deflections simultaneously into a product. Typically up to 4 synchronized input channels are available. Load profiles include pure sinusoidal, step input, shock, block cycle, frequency spectrum, resonant dwell and road-load recorded inputs. A wide variety of environments can be included in a fatigue test such as temperature (-80 º F to 350º F), salt spray, Arizona & JIS test dusts and ozone.

Typical products tested include:

- Automotive components, mounts, bushings, sway bars, brackets, fasteners, exhaust hangers, drive shafts, U-joints, half shafts, steering train, shock absorbers, dampers and vibration absorbers. Air induction ducts are tested for vacuum collapse, fatigue, cuff pull-off, leak and chemical resistance

- Rail components, bolster springs, direct fixation fasteners (DFF)

- Biomedical products, bone screws and plates, implant devices, surgical implements, dental implants, tubing and prosthesis-es

- Mechanical goods, rollers, couplings, drives, bridge bearings, earthquake bearings, machinery vibration mounts, hose couplings and assemblies

- Heavy Truck suspensions, frame components, bushings, torque rods, bearings torsional springs and leaf springs.

- Sporting goods, rifle recoil pads, chest impact protectors, padding, shoe sole foams, golf clubs, golf balls, protective helmets

- Electronic components, disk drives, LCD displays, handheld devices

- Military products, tank track pads and bushings, bogie wheels, fabrics and fasteners